Micro-Trains Line Thrall 60-Foot ‘Opera Window’ Centerbeam Flat Car

Published: 2023-06-05 - By: CNW400

Last updated on: 2023-06-04

Last updated on: 2023-06-04

visibility: Public - Headline

Prototype History

The North American railroads and lumber industry had a long-time predicament of transporting wood and other building materials. At first, standard boxcars were the traditional method as the enclosed railcar offered protection from the elements. But this process proved to be labor intensive and time consuming as cargo was maneuvered through the sliding side doors – at times one board at a time. Flatcars were also utilized --- loading and unloading was much easier but the loads were exposed and prone to shift.

With the dawn of the 1960s, the McCloud River Railroad (primarily a logging railroad based in California from 1897 to 2010) tried to conquer this problem with two concepts. The first idea was an open top boxcar along the design of a gondola – this approach was quickly abandoned.

The next solution proposed was the all-door or full-door boxcar arrangement. A 60-foot railcar with fixed ends and roof with four huge sliding doors that could give easy access to half of the car with various open-door configurations (a previous Southern Railway brainstorm that never made it pass the drawing board was using roll-up doors similar to a storage locker). The all-door prototype was constructed in 1962 and became a favorite for the Pacific Northwest lumber companies. But the usage of these railcars met a quick demise by the mid-1970s as the full-door boxcar proved to be too complex and too expensive with high maintenance issues related to all those moving parts. Later bulkhead flatcars were seen as an alternative as the lumber industry began to introduce bundled and wrapped loads. The bulkhead cars could more easily be loaded and unloaded with forklift trucks but shifting of load weight was still an issue with these modified flatcars.

Then in 1977, the Thrall Car Company built the first centerbeam railcar --- a modified bulkhead flatcar with a longitudinal I-beam down the middle of the car for reinforcement and a center wall or steel girder arrangement to secure loads. The idea was conceived by Canadian National in 1969 and the design rights were granted to Thrall. After eight years of research and development, the 60’-8” (length between the bulkheads) centerbeam was released with initial orders to Burlington Northern (190 cars), Milwaukee Road (100), and Union Pacific (75) ...Western Pacific was soon to follow.

Again, the basic design of the centerbeam is a bulkhead flatcar with the earlier versions having 60- to 73-feet of interior deck length. A horizontal beam braces a center wall which supports the cargo with steel cables that wrap around the lumber load and hook onto the wall beam. The cables are then tightened with a tie-down winch. When the flat car is empty, the cables are secured to the wall or truss-beams. The deck of the centerbeam slants slightly inward to keep the load stable. The centerbeam car is designated Class FBC or FBS by the Association of American Railroads (AAR): “Flat car constructed with a center beam above the car deck from bulkhead to bulkhead. When cars are equipped with permanent racks for stowing parts or are specially modified or equipped to provide for loading of a particular commodity, the letter "S" should be affixed to the applicable designating letters.”

There are two primary designs for centerbeam cars – the opera window and truss. The opera window arrangement was used first. A center I-beam supported with vertical posts and steel sheet wall with tall oval holes cut into the panel wall to reduce car weight – allowing over 15,000 pounds of additional load capacity than a conventional bulkhead car. Initially, Thrall and Gunderson offered a 60-foot version followed by the more popular 73-foot model. Both manufacturer designs were similar with the most obvious spotting difference of Thrall having 12 equal sized oval holes while Gunderson also having 12 ovals but the two end holes are cut smaller than the middle ten. The same for the 73-foot car --- Thrall has 13 same-sized oval windows and Gunderson has 14 ovals on early versions, then 13 on later models with the two end openings with different sized cut-outs.

During the late 1980s, a lighter truss-style design was introduced. Once more, a horizontal I-beam held with vertical posts but this time with diagonal crossing braces. Most car builders used similar truss designs with Thrall being the easiest to identify with no crisscrossing beams and large end panels.

Centerbeam cars are favored to haul such items as lumber, plywood, wallboard, and building posts because they can be loaded and unloaded easily by forklift and more quickly with work being done simultaneously on each side. Care must be taken to assure that the car is loaded/unloaded evenly with equal weight distribution to avoid tipping. This efficiency allows the material to hit the market faster and returns the railcar back into revenue service.

The 60-foot cars typically haul green lumber (freshly harvested wood with a high moisture content) and more dense, heavier plasterboard and laminate products. The 73-foot centerbeams carry finished lumber and plywood. The larger 73-foot car can transport 200,000 pounds of construction material – that is enough framing lumber to build six average size houses (Source: AAR). Untreated and sensitive loads are bundled and wrapped with a polyethylene scrim to protect from the weather. Treated lumber is often unwrapped. A safety issue for the centerbeam flatcar is the need for speed restrictions when hauling an empty car. Centerbeam cars are lightweight when empty and an unloaded flatcar may experience ‘hunting’ oscillation or swaying when travelling over 50 mph. To avoid wobbling and the risk of derailments an empty centerbeam puts a locomotive at a speed restriction of below 50 mph. In contrast, a loaded car with plywood or lumber may travel at speeds up to 60 mph (Source: Union Pacific).

The early-2000s saw the introduction of the 81-foot FleXibeam from FreightCar America. The FleXibeam has a lowered horizontal center beam with a distinctive X-bracing pattern that runs along the entire length of the car and a weight capacity of 216,000 pounds.

The use of railcars to transport lumber and wood products is still going strong with over 400,000 carloads of wood products shipped in 2022 according to the Association of American Railroads (AAR).

Road Names and Pricing

The Micro-Trains Line company has enjoyed a long history of being one of the industry leaders in N Scale railroading with high standards of excellence. Their vast inventory of model railcars includes almost 70 centerbeam flatcars in the 60-foot opera-window and truss-style versions. The release dates for these models range from 1995 to 2023. The following road names are represented in their centerbeam flatcar product line:- Burlington Northern

- Burlington Northern Santa Fe

- Canadian National

- Canadian Pacific

- Centex

- CSX Transportation

- Domtar

- McCloud River

- Milwaukee Road

- Norfolk Southern

- Northwestern Oklahoma

- TTX Company

- Union Pacific

- Western Pacific

- Undecorated

- Special Holiday Theme

The Model

The centerbeam flatcar arrived in a rigid oversized clear plastic jewel case with a slip-off cover and one-piece plastic cradle to cushion the model. A thin plastic sheet was placed over the top of the car to protect it from blemishes during shipping. The model information is clearly labeled on the end of the case for ease to locate when in storage and no additional detail parts were found in the container.

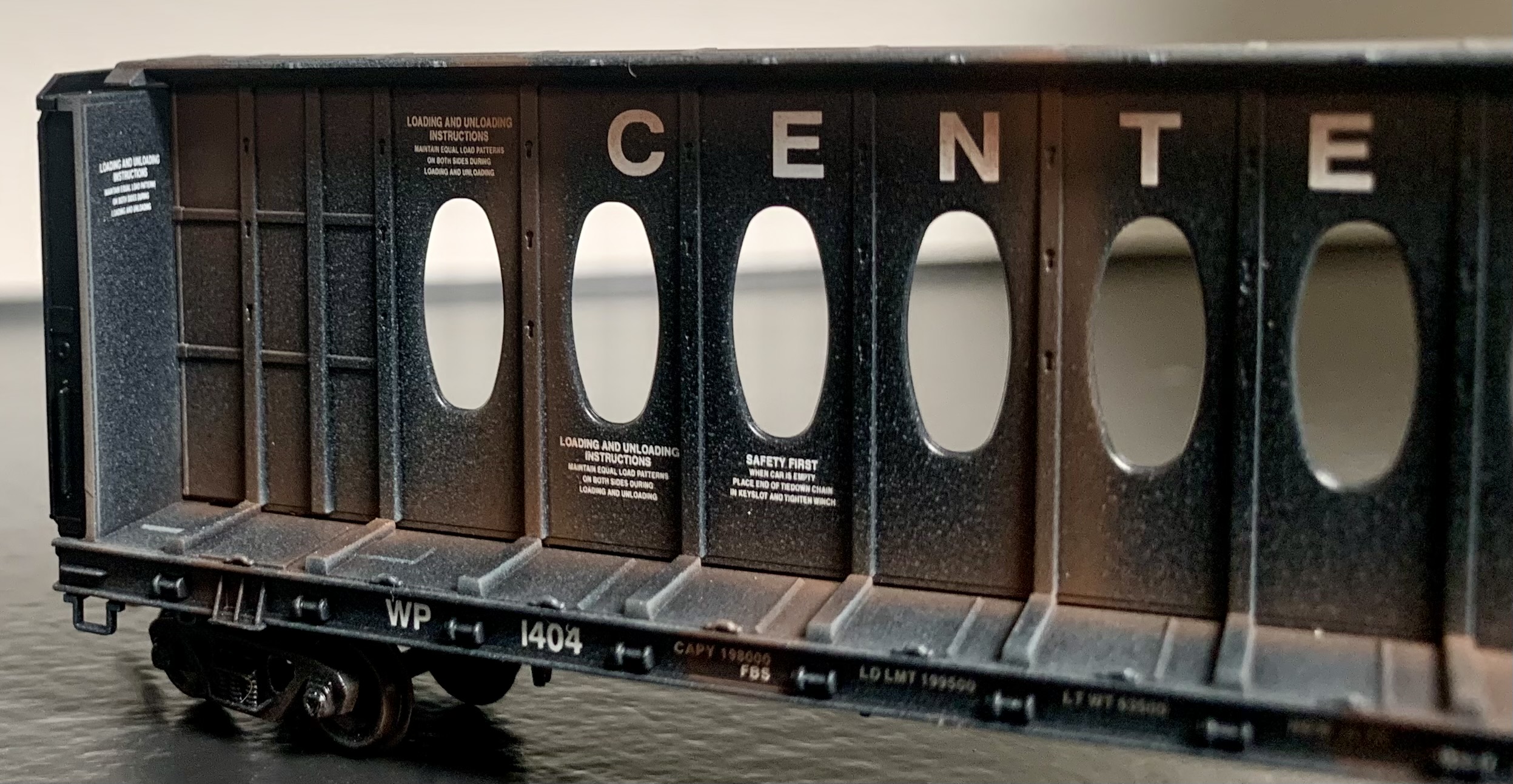

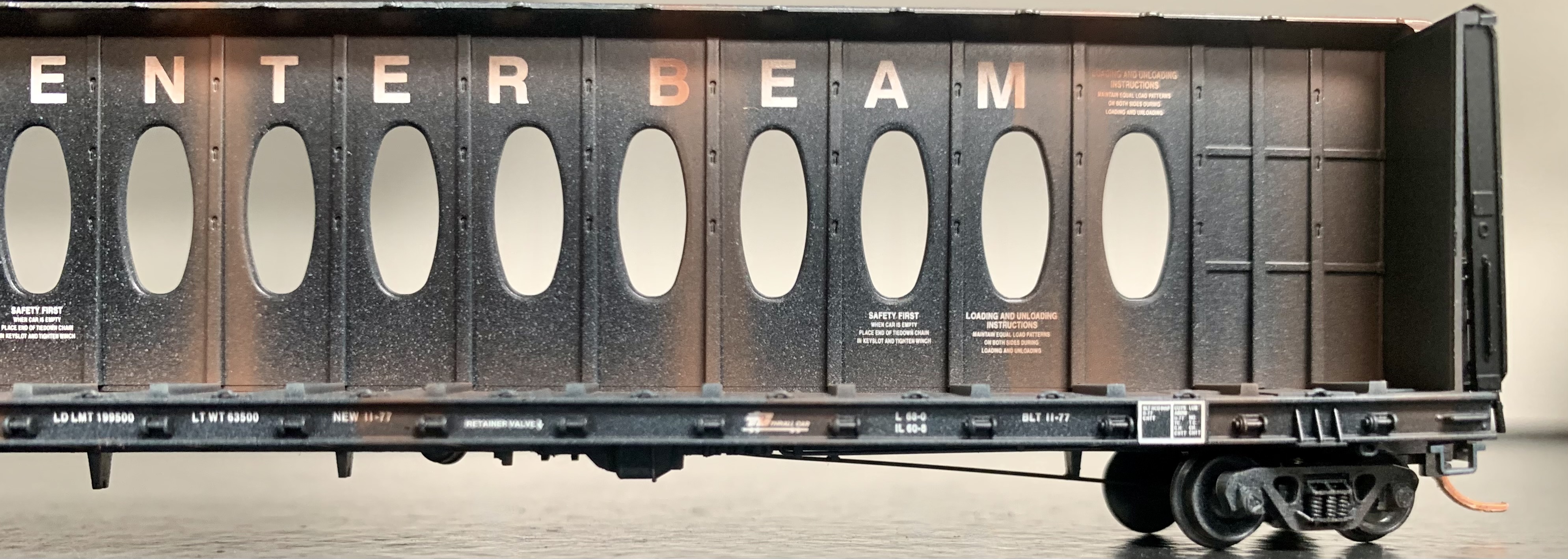

The base paint job is smooth and even along the entire injection molded plastic model. The flatcar is painted black with white lettering for the Western Pacific Railroad (WP). Western Pacific owned ten Thrall opera centerbeam cars numbered 1401 through 1410 – several of these flatcars made their way to the Northwestern Oklahoma Railroad (NOKL) after the Union Pacific (UP) purchased the Western Pacific in 1982. The model is tastefully factory weathered with light road dirt brown and misted with a touch of grey.

The Micro-Trains Line centerbeam wall features prototype correct twelve-opera window holes and solid panels with a waffle pattern on each end. Several caution notices are neatly stenciled on the steel wall panels stressing the need to maintain equal weight distribution when loading & unloading and to properly tiedown load cables and tighten with the winch when car is empty. The car deck is divided into separate panel section with a straight bottom side sill with the proper fifteen winch spool configuration to secure cabling. Other side car details include nicely sized stirrup steps, molded grab irons loacted on the end structual walls and a data placard mounted on the bottom sill.

The car ends are very delicate with fine detail parts molded onto a separately applied support beam grid. Both ends display the correct Thrall hortizontal and vertical beam pattern with a full ladder and top grab iron on the car left, five rung ladder on the car right and a crossover platform. The B-end displays an Universal brake wheel with an elegant-looking brake chain. The lettering is neat and in proper arrangement with the road marker & road number in the top right corner with additional data remarks. Loading and unloading warnings are again displayed on each end. NOTE – the smooth end panels and lettering are not weathered like the rest of the car...a minor production flaw for an otherwise exceptional model.

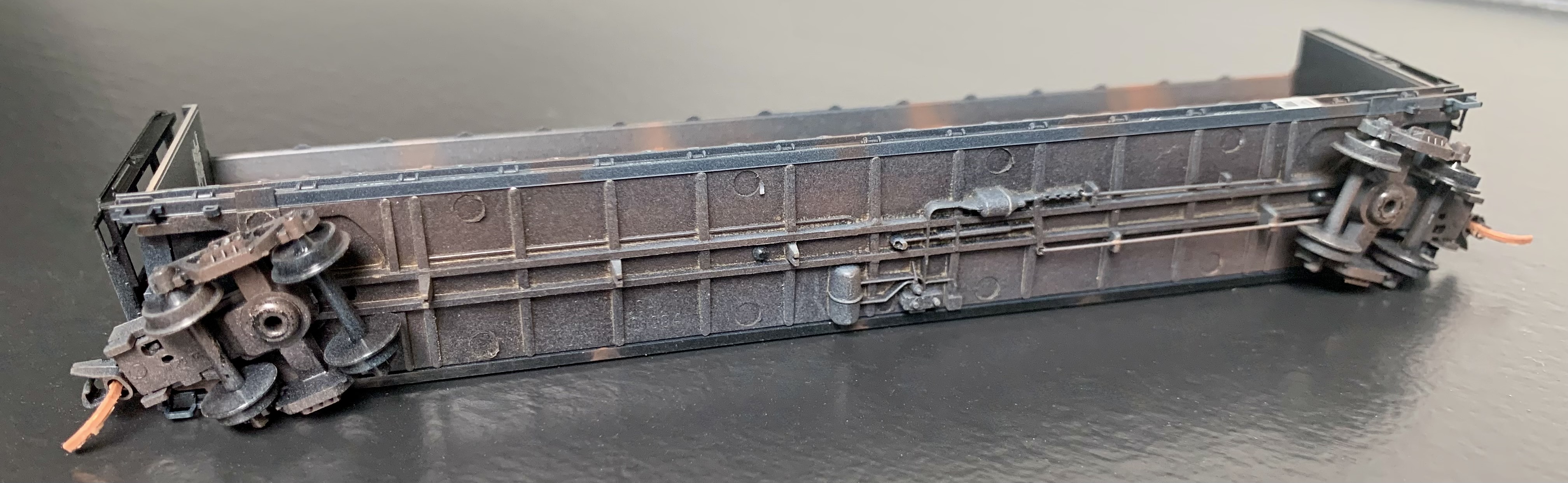

The underside is handsomely structured with air reservoir, brake cylinder, control valve, and a wire brake lever that is visible from trackside --- a pleasant surprise of detail attention that makes for an attractive N scale model. Micro-Trains hid their production marks on the belly of the car (eight circles). The centerbeam car rides on 100-ton American Steel (ASF) ‘ride control’ trucks and 36’ scale wheels. The flatcar is fitted with Micro-Trains Magne-Matic knuckle couplers and injection molded black plastic wheels. Both truck-mounted couplers were aligned to the proper height. The use of plastic wheels is disappointing, and I will be upgrading to metal wheels in the future for better performance and sound.

The car measures 4 3/4 inches in length and weighs about 0.7 ounces, which is extremely underweight according to the National Model Railroad Association (NMRA) recommendations (which is 1.24 ounces for this size car). I found it a good runner while testing the car on Kato Unitrack with no issues around curves and minimal wobbling through turnouts at slow and medium speeds.* I found the car well-balanced when empty – but a homemade or secondary market lumber load can help boost the desired amount of operating weight while adding a dash of real-life road operations. The minimum recommended running radius is 9 3/4”. *Model was tested as an individual centerbeam car between boxcars – can not speak for operating conditions when a string of centerbeam cars are latched together in a series.

In closing, another strong representation in the Micro-Trains Line collection. A prototypical model with admirable attention to detail for an oft forgotten railcar...pleasing weathering touches and visionally striking underside assembly making for an attractive model. A well-balanced, smooth riding car that surprisingly needs no adjustment. Aside from two minor complaints (ends not fully weathered and plastic wheels), I am extremely pleased to add this Micro-Trains model to my layout.