N Scale of Nevada - 07-99 - Loader, Piggy Packer, FWD, PC-60

Click to see the details

market

Click to see the details

history

Click to see the details

collector

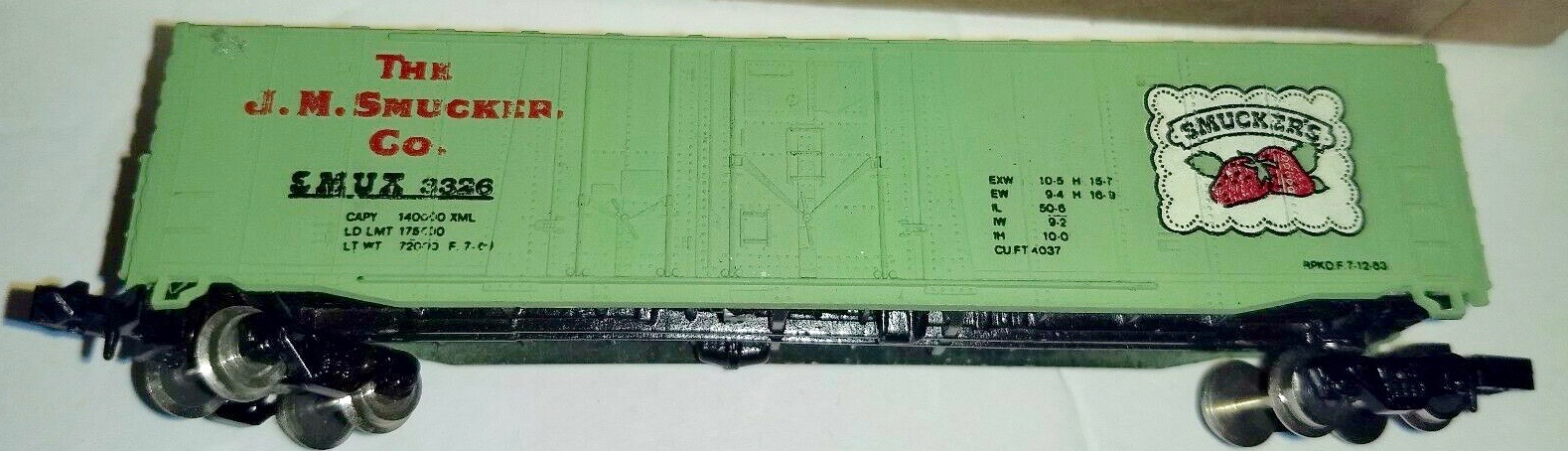

| Stock Number | 07-99 |

| Brand | N Scale of Nevada |

| Manufacturer | N Scale of Nevada |

| Body Style | Wheels of Time Raygo Wagner PC-90 Piggy Packer |

| Prototype Vehicle | Truck, Intermodal, Piggy-Packer (Details) |

| Prototype | Loader, Piggy Packer, FWD, PC-60 |

| Ready-to-Run | No |

| Kit Complexity | Craftsman |

| Release Date | 1989-11-01 |

| Item Category | Vehicles |

| Model Type | Loader |

| Model Subtype | Piggy Packer |

| Model Variety | FWD PC-60 |

| Prototype Region | North America |

| Prototype Era | NA Era V: Modern Diesel (1979 - Present) |

| Scale | 1/160 |

Prototype History:

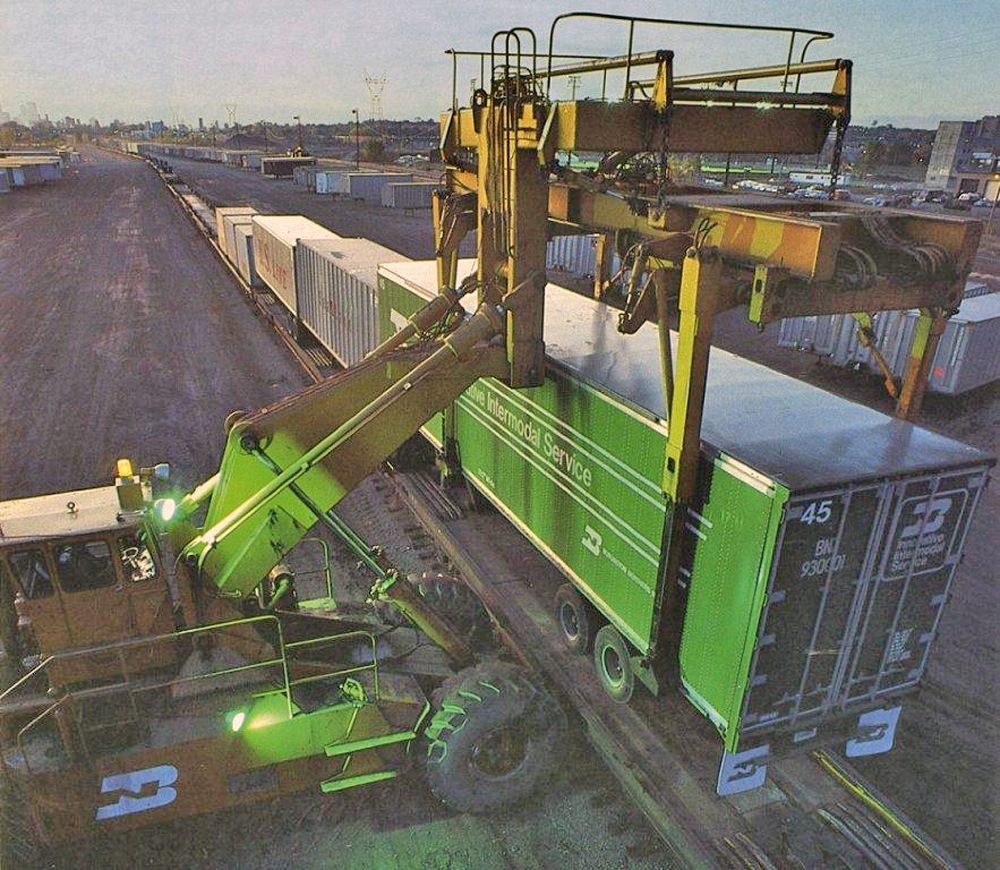

By the early 1960s, railroads in North America were routinely transporting truck trailers on specialized railroad cars called “piggyback” flat cars (known as Trailer On Flat Car, or TOFC). The loading and unloading of truck trailers from these flat cars was accomplished by way of a ramp at one end of the train, with a truck-tractor used to pull the trailer on and off the train. This was commonly referred to as “circus loading”, and was a time consuming process: by this method, trailers on piggyback flat cars could only be loaded or unloaded sequentially. Furthermore circus loading required a very skilled driver, one able to navigate the narrow confines of a flatcar, especially when backing up to pick up a trailer.

In 1968, the FWD Wagner Corp. developed the P-80 and the PC-90. The boom on the PC-90 (and P-80) was redesigned to eliminate the tilting of the trailers during lifting by including a pair of horizontal stabilizing bars that served as a parallelogram. Folding grapple arms replaced the clamshell lift mechanism, eliminating the 10-feet clearance required with the '70. Further, by 1968, ISO standards had been established for the emerging maritime container business, replacing the proprietary lift mechanisms for SeaLand, Matson and others. Nelson saw the growth potential in adapting the Piggy-Packer for container handling, and chose the lift mechanism that had been developed by Ropco Corp. The first dual-purpose machine equipped with a container spreader entered service in UP’s Seattle facility in 1968. Furthermore, lift capacity was beefed up to 90,000 lb (45 tons). The PC-90 quickly became the de facto standard for mechanization of TOFC operations.

In 1968, the FWD Wagner Corp. developed the P-80 and the PC-90. The boom on the PC-90 (and P-80) was redesigned to eliminate the tilting of the trailers during lifting by including a pair of horizontal stabilizing bars that served as a parallelogram. Folding grapple arms replaced the clamshell lift mechanism, eliminating the 10-feet clearance required with the '70. Further, by 1968, ISO standards had been established for the emerging maritime container business, replacing the proprietary lift mechanisms for SeaLand, Matson and others. Nelson saw the growth potential in adapting the Piggy-Packer for container handling, and chose the lift mechanism that had been developed by Ropco Corp. The first dual-purpose machine equipped with a container spreader entered service in UP’s Seattle facility in 1968. Furthermore, lift capacity was beefed up to 90,000 lb (45 tons). The PC-90 quickly became the de facto standard for mechanization of TOFC operations.

Item created by: nscalemodeler160

on 2016-04-14 15:10:45

Last edited by: gdm on 2020-06-01 09:40:34

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.

Last edited by: gdm on 2020-06-01 09:40:34

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.