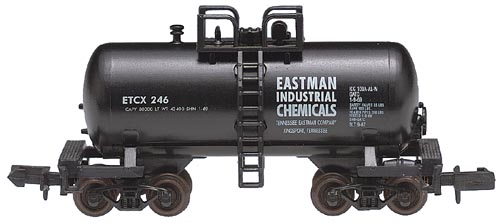

Atlas - 50 000 408 - Tank Car, Single Dome, Trinity 25,500 - AG Processing - 251178

| Stock Number | 50 000 408 |

| Brand | Atlas |

| Manufacturer | Atlas |

| Body Style | Atlas Tank Car 25,500 Gallon Trinity |

| Image Provider's Website | Link |

| Prototype Vehicle | Tank Car, Single Dome, Trinity 25,500 (Details) |

| Road or Company Name | AG Processing (Details) |

| Reporting Marks | TILX |

| Road or Reporting Number | 251178 |

| Paint Color(s) | Black / White / Yellow |

| Coupler Type | AccuMate Magnetic Knuckle |

| Coupler Mount | Truck-Mount |

| Wheel Type | Injection Molded Plastic |

| Wheel Profile | Small Flange (Low Profile) |

| Release Date | 2010-06-01 |

| Item Category | Rolling Stock (Freight) |

| Model Type | Tank Car |

| Model Subtype | Trinity |

| Model Variety | 25.5K |

| Prototype Region | North America |

| Prototype Era | NA Era V: Modern Diesel (1979 - Present) |

| Scale | 1/160 |

| Track Gauge | N standard |

Model Information:

This model was first released by Atlas in September of 2009. It features: numerous detail fittings and components specific to prototype, a highly detailed body with prototypical jacket seams, and a see-through walkway and top platform grating.

Prototype History:

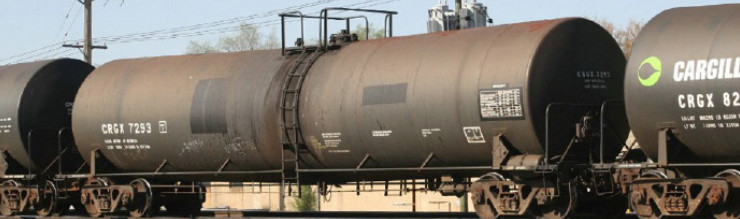

This Trinity tank car is in the typical condition of tank cars that

have been hauling relatively clean commodities for decades.

There is evidence of years of sun bleaching and rain-washed

dust. The darker black areas are the positions of the original Cargill logos, which suggests that the remainder of the car has not

been painted or cleaned (on the outside) in that 20-year period. When this Trinity CRX7293 tank car was photographed 20 years after the car was built the original Cargill logos had

been painted over with black so only the white reporting

marks identify the owner (or lessor). A number of firms took

this identity-loss precaution after television photos of train

wrecks provided adverse publicity for any type of tank car

(although the vegetable oils that these cars would carry are

relatively harmless).

Road Name History:

The history of Ag Processing Inc (AGP) begins in 1983. At that time, Land O’Lakes, Farmland Industries, and Boone Valley Cooperative Processing Association entered into a joint venture agreement to form one cooperative soybean processing company. The joint venture was formalized into an Iowa cooperative company and took the name Ag Processing Inc (AGP). Over thirty years later, AGP is the largest cooperative soybean processing company in the world.

Today, AGP is a growing and successful company that employs approximately 1,100 people and markets U.S. agricultural products around the world.

Soy far, soy good for Ag Processing (AGP), the largest farmer-owned soybean processor in the world, and roughly the fourth-largest soybean processor in the US based on capacity. It purchases and processes more than 5.5 million acres of members' soybeans per year. The farmer-owned cooperative is also a leading supplier of refined vegetable oil in the US. It procures, processes, markets, and transports grains and grain products, ranging from human food ingredients to livestock feed to renewable fuels. AGP is owned by about 180 local and regional cooperatives and represents more than 250,000 farmers in 15 states throughout the US.

Soy far, soy good for Ag Processing (AGP), the largest farmer-owned soybean processor in the world, and roughly the fourth-largest soybean processor in the US based on capacity. It purchases and processes more than 5.5 million acres of members' soybeans per year. The farmer-owned cooperative is also a leading supplier of refined vegetable oil in the US. It procures, processes, markets, and transports grains and grain products, ranging from human food ingredients to livestock feed to renewable fuels. AGP is owned by about 180 local and regional cooperatives and represents more than 250,000 farmers in 15 states throughout the US.

Brand/Importer Information:

In 1924 Stephan Schaffan, Sr. founded the Atlas Tool Company in Newark, New Jersey. In 1933 his son, Stephan Schaffan, Jr., came to work for his father at the age of sixteen. Steve Jr. built model airplanes as a hobby and frequented a local hobby shop. Being an enterprising young man, he would often ask the owner if there was anything he could do to earn some extra spending money. Tired of listening to his requests, the hobby-store owner threw some model railroad track parts his way and said, "Here, see if you can improve on this".

In those days, railroad modelers had to assemble and build everything from scratch. Steve Jr. created a "switch kit" which sold so well, that the entire family worked on them in the basement at night, while doing business as usual in the machine shop during the day.

Subsequently, Steve Jr. engineered the stapling of rail to fiber track, along with inventing the first practical rail joiner and pre-assembled turnouts and flexible track. All of these products, and more, helped to popularize model railroading and assisted in the creation of a mass-market hobby. The budding entrepreneur quickly outgrew the limitations of a basement and small garage operation. Realizing they could actually make a living selling track and related products, Steve and his father had the first factory built in Hillside, New Jersey at 413 Florence Avenue in 1947. On September 30, 1949, the Atlas Tool Company was officially incorporated as a New Jersey company.

In 1985, Steve was honored posthumously for his inventions by the Model Railroad Industry Association and was inducted into the Model Railroad Industry Hall of Fame in Baltimore, Maryland. In addition, Steve was nominated and entered into the National Model Railroad Association Pioneers of Model Railroading in 1995.

In the early 1990s, the Atlas Tool Company changed its name to Atlas Model Railroad Company, Inc.

In those days, railroad modelers had to assemble and build everything from scratch. Steve Jr. created a "switch kit" which sold so well, that the entire family worked on them in the basement at night, while doing business as usual in the machine shop during the day.

Subsequently, Steve Jr. engineered the stapling of rail to fiber track, along with inventing the first practical rail joiner and pre-assembled turnouts and flexible track. All of these products, and more, helped to popularize model railroading and assisted in the creation of a mass-market hobby. The budding entrepreneur quickly outgrew the limitations of a basement and small garage operation. Realizing they could actually make a living selling track and related products, Steve and his father had the first factory built in Hillside, New Jersey at 413 Florence Avenue in 1947. On September 30, 1949, the Atlas Tool Company was officially incorporated as a New Jersey company.

In 1985, Steve was honored posthumously for his inventions by the Model Railroad Industry Association and was inducted into the Model Railroad Industry Hall of Fame in Baltimore, Maryland. In addition, Steve was nominated and entered into the National Model Railroad Association Pioneers of Model Railroading in 1995.

In the early 1990s, the Atlas Tool Company changed its name to Atlas Model Railroad Company, Inc.

Item created by: Steve German

on 2016-04-24 10:48:35

Last edited by: gdm on 2020-06-06 09:00:52

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.

Last edited by: gdm on 2020-06-06 09:00:52

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.