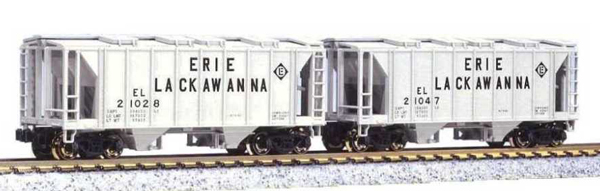

Kato USA - 186-0201 - Covered Hopper, 2-Bay, ACF 36 Foot - Erie Lackawanna - 21019 & 21035

Click to see the details

market

Click to see the details

history

| Stock Number | 186-0201 |

| Original Retail Price | $27.95 |

| Brand | Kato USA |

| Manufacturer | Kato |

| Body Style | Kato Covered Hopper 2-Bay 70 Ton |

| Image Provider's Website | Link |

| Prototype Vehicle | Covered Hopper, 2-Bay, ACF 36 Foot (Details) |

| Road or Company Name | Erie Lackawanna (Details) |

| Reporting Marks | EL |

| Road or Reporting Number | 21019 & 21035 |

| Paint Color(s) | Gray |

| Print Color(s) | Black |

| Coupler Type | Kato Operating Knuckle |

| Wheel Type | Nickel-Silver Plated Metal |

| Wheel Profile | Small Flange (Low Profile) |

| Multipack | Yes |

| Multipack Count | 2 |

| Multipack ID Number | 186-0201 |

| Release Date | 1998-11-01 |

| Item Category | Rolling Stock (Freight) |

| Model Type | Covered Hopper |

| Model Subtype | 2-Bay |

| Model Variety | 70 Ton |

| Prototype Region | North America |

| Prototype Era | NA Era IV: 2nd Gen Diesel (1958 - 1978) |

| Scale | 1/160 |

| Track Gauge | N standard |

Specific Item Information:

Set 1

Prototype History:

This design had a life span that is truly enormous. The last cars of this design were built in the 1960's -- three decades after the first cars were built for Santa Fe. Quite a few of these cars are still in service. Because you have to stand on the roof in order to open the hatches, these cars were immune from the "No Roof Walk" rule of 1964, but a number would be scrapped when friction bearing trucks were outlawed. Amazingly, some cars are now being retired because they have hit the Federal Railroad Administration's 50 year rule!

Originally designed at the height of the Great Depression, the first ten cars of this design were delivered to Santa Fe in an austere black paint scheme. Covered hoppers have always been used for any bulk cargo that had to be protected from the elements. Some have the impression that covered hoppers are used mostly for grain. Nothing can be further from the truth. In fact, moving grain in covered hoppers has only been commonplace since the 1960's. Before that period, most grain moved in 40' box cars with grain doors temporarily nailed over the doorways. In the steam era, covered hoppers were used for cement, sand, clay, talc, and other powders. The cargo was loaded through eight square hatches in the roof. To empty the car, the hatches at the bottom are opened and the load spills out. At this point, some low man on the company ladder would have to climb into the car with a broom and sweep out the corners and the center sill. The American Car & Foundry covered hopper design was such a success that it became a defacto standard for years. Even Pullman Standard (ACF's arch enemy) built cars to the same design. The distinctive open triangles in the sides make these cars easily distinguishable even from a distance. ACF would also develop a version without the open triangles which was not as prolific as the version presented here. Amazingly, many of these cars are still in use today, in MOW and lineside service. Many have been rebuilt as ballast hoppers, including for SP, CSX, Amtrak, and Santa Fe.

Originally designed at the height of the Great Depression, the first ten cars of this design were delivered to Santa Fe in an austere black paint scheme. Covered hoppers have always been used for any bulk cargo that had to be protected from the elements. Some have the impression that covered hoppers are used mostly for grain. Nothing can be further from the truth. In fact, moving grain in covered hoppers has only been commonplace since the 1960's. Before that period, most grain moved in 40' box cars with grain doors temporarily nailed over the doorways. In the steam era, covered hoppers were used for cement, sand, clay, talc, and other powders. The cargo was loaded through eight square hatches in the roof. To empty the car, the hatches at the bottom are opened and the load spills out. At this point, some low man on the company ladder would have to climb into the car with a broom and sweep out the corners and the center sill. The American Car & Foundry covered hopper design was such a success that it became a defacto standard for years. Even Pullman Standard (ACF's arch enemy) built cars to the same design. The distinctive open triangles in the sides make these cars easily distinguishable even from a distance. ACF would also develop a version without the open triangles which was not as prolific as the version presented here. Amazingly, many of these cars are still in use today, in MOW and lineside service. Many have been rebuilt as ballast hoppers, including for SP, CSX, Amtrak, and Santa Fe.

Road Name History:

The Erie Lackawanna Railway (reporting mark EL), known as the Erie Lackawanna Railroad until 1968, was formed from the 1960 merger of the Erie Railroad and the Delaware, Lackawanna & Western Railroad. The official motto of the line was "The Friendly Service Route".

The Erie Lackawanna Railway (reporting mark EL), known as the Erie Lackawanna Railroad until 1968, was formed from the 1960 merger of the Erie Railroad and the Delaware, Lackawanna & Western Railroad. The official motto of the line was "The Friendly Service Route".

Like many railroads in the northeast already financially vulnerable from the expanding U.S. Interstate Highway System, the line was severely weakened fiscally by the extent, duration and record flood levels due to Hurricane Agnes in 1972. It would never recover, and most of the corporation's holdings were subsumed into the federal rescue purchases creating Conrail in 1976, ending its days as an operating railroad company.

Read more on Wikipedia.

Like many railroads in the northeast already financially vulnerable from the expanding U.S. Interstate Highway System, the line was severely weakened fiscally by the extent, duration and record flood levels due to Hurricane Agnes in 1972. It would never recover, and most of the corporation's holdings were subsumed into the federal rescue purchases creating Conrail in 1976, ending its days as an operating railroad company.

Read more on Wikipedia.

Brand/Importer Information:

KATO U.S.A. was established in 1986, with the first U.S. locomotive model (the GP38-2, in N-Scale) released in 1987. Since that time, KATO has come to be known as one of the leading manufacturers of precision railroad products for the modeling community. KATO's parent company, Sekisui Kinzoku Co., Ltd., is headquartered in Tokyo, Japan.

In addition to producing ready-to-run HO and N scale models that are universally hailed for their high level of detail, craftsmanship and operation, KATO also manufactures UNITRACK. UNITRACK is the finest rail & roadbed modular track system available to modelers today. With the track and roadbed integrated into a single piece, UNITRACK features a nickel-silver rail and a realistic-looking roadbed. Patented UNIJOINERS allow sections to be snapped together quickly and securely, time after time if necessary.

The Kato U.S.A. office and warehouse facility is located in Schaumburg, Illinois, approximately 30 miles northwest of Chicago. All research & development of new North American products is performed here, in addition to the sales and distribution of merchandise to a vast network of wholesale representatives and retail dealers. Models requiring service sent in by hobbyists are usually attended to at this location as well. The manufacturing of all KATO products is performed in Japan.

Supporters of KATO should note that there is currently no showroom or operating exhibit of models at the Schaumburg facility. Furthermore, model parts are the only merchandise sold directly to consumers. (Please view the Parts Catalog of this website for more specific information.)

In addition to producing ready-to-run HO and N scale models that are universally hailed for their high level of detail, craftsmanship and operation, KATO also manufactures UNITRACK. UNITRACK is the finest rail & roadbed modular track system available to modelers today. With the track and roadbed integrated into a single piece, UNITRACK features a nickel-silver rail and a realistic-looking roadbed. Patented UNIJOINERS allow sections to be snapped together quickly and securely, time after time if necessary.

The Kato U.S.A. office and warehouse facility is located in Schaumburg, Illinois, approximately 30 miles northwest of Chicago. All research & development of new North American products is performed here, in addition to the sales and distribution of merchandise to a vast network of wholesale representatives and retail dealers. Models requiring service sent in by hobbyists are usually attended to at this location as well. The manufacturing of all KATO products is performed in Japan.

Supporters of KATO should note that there is currently no showroom or operating exhibit of models at the Schaumburg facility. Furthermore, model parts are the only merchandise sold directly to consumers. (Please view the Parts Catalog of this website for more specific information.)

Item created by: gdm

on 2016-09-21 09:36:33

Last edited by: CNW400 on 2020-08-19 09:33:02

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.

Last edited by: CNW400 on 2020-08-19 09:33:02

If you see errors or missing data in this entry, please feel free to log in and edit it. Anyone with a Gmail account can log in instantly.